Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

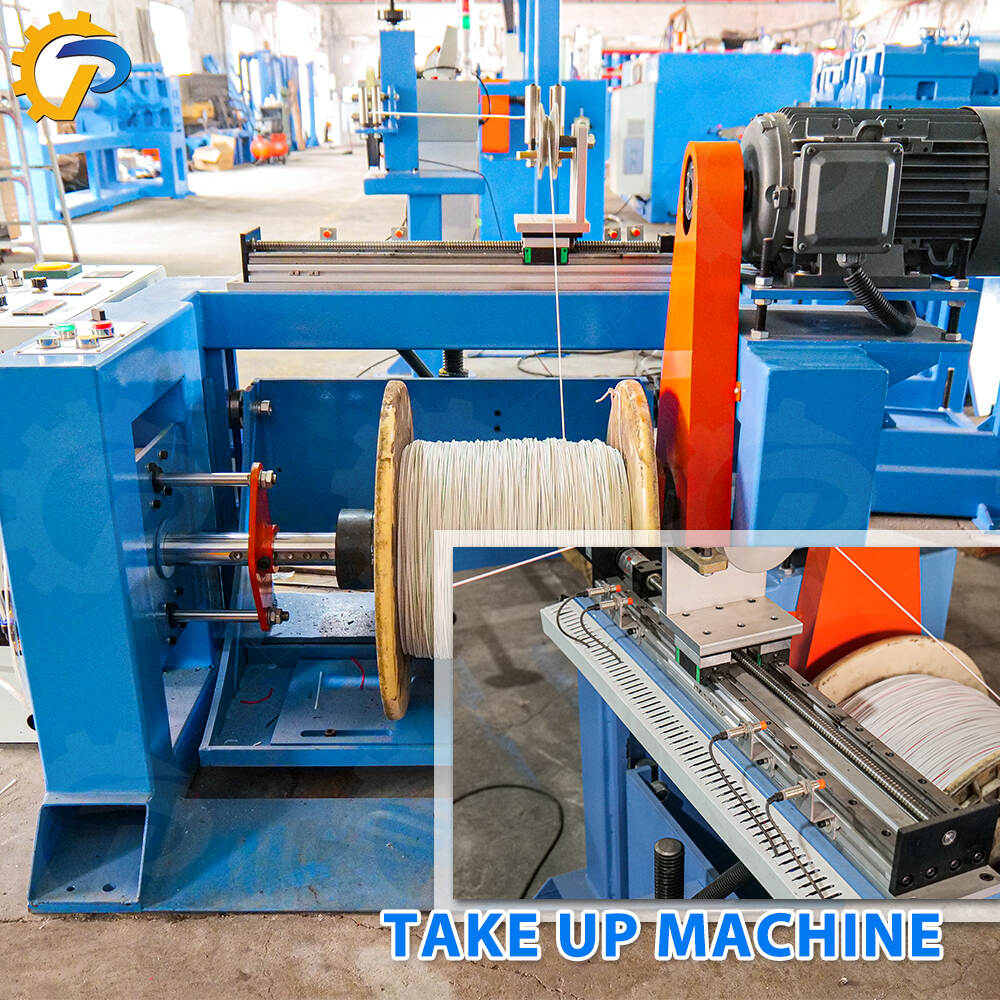

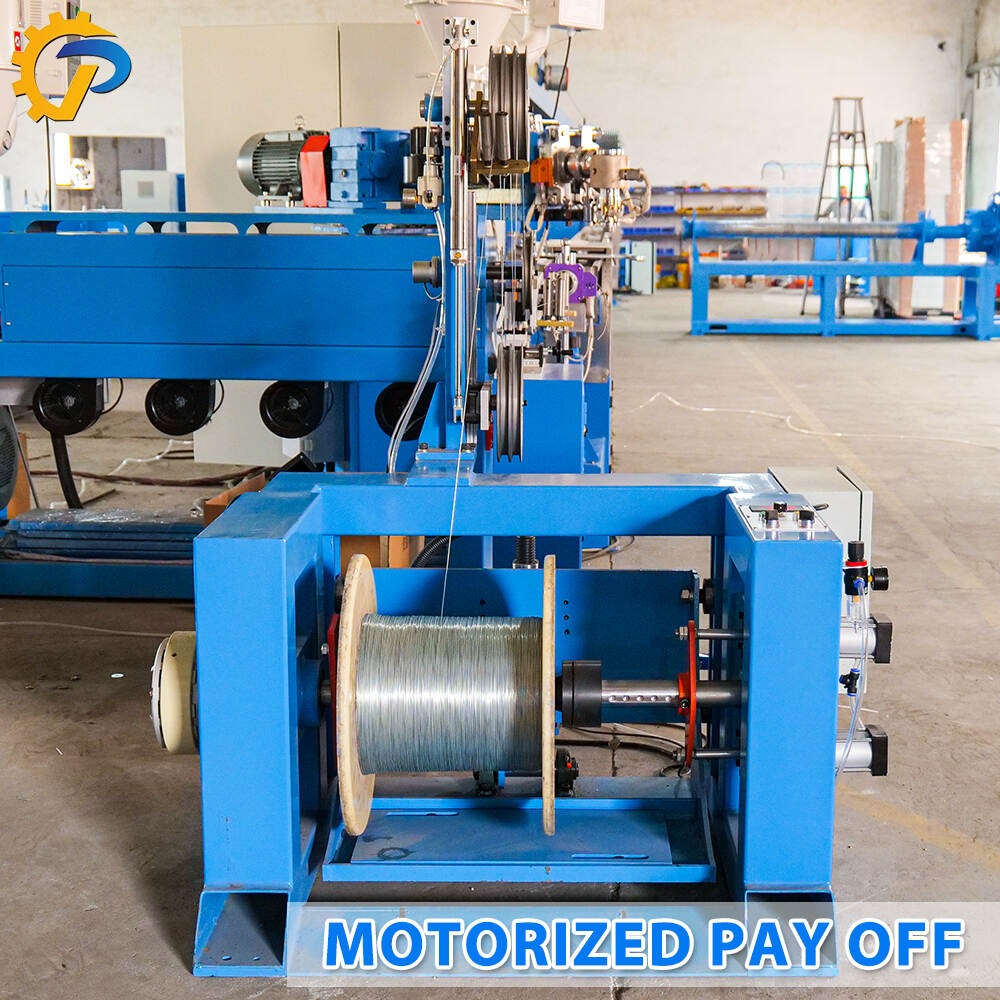

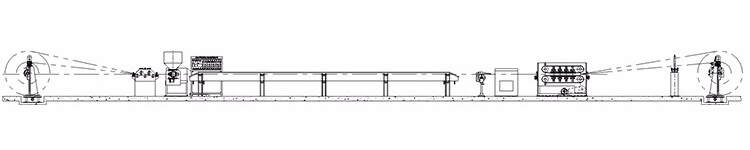

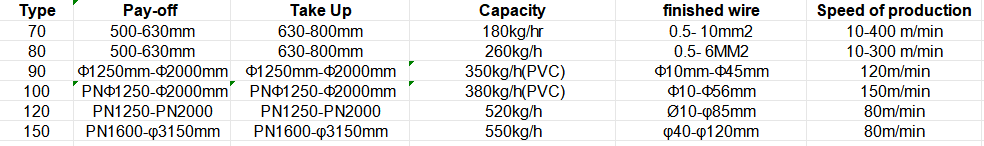

70+35 Cables Manufacturing Data Building Copper Electrical Wire Cable Making Machinery Extruder Extrusion Sheath Machine

The 70+35 Cable Extrusion Machine is a high-performance jacketing and sheathing extrusion line designed for manufacturing insulated and sheathed building cables. Ideal for PVC, PE, and XLPE materials, it supports double-color extrusion and two-wheel traction. With dual extruders (φ70mm and φ35mm), this machine ensures superior flexibility, high output, and reliable operation across a wide range of cable production needs in the electrical industry.

Product Features

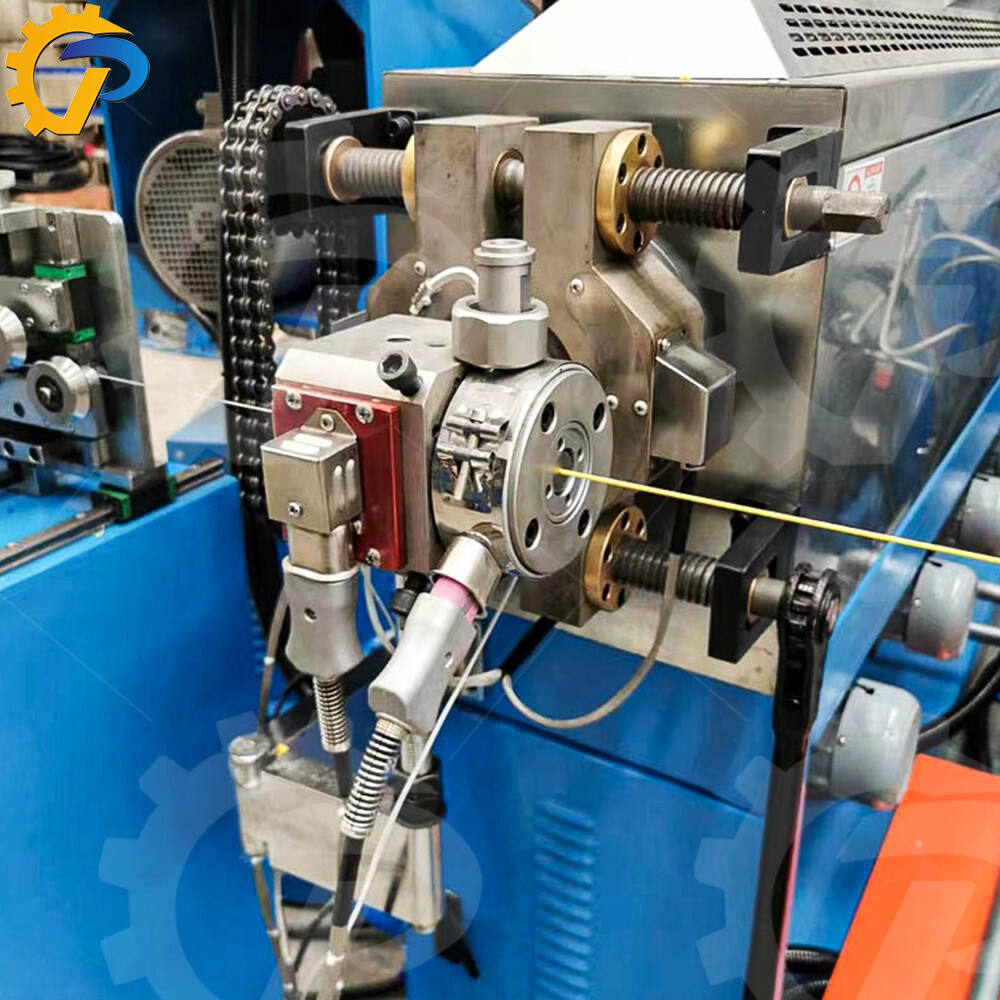

Dual Extruder Design for Multi-Color and Multi-Layer Extrusion

Equipped with both φ70mm and φ35mm extruders, the machine supports two-color or double-layer cable extrusion, enhancing product versatility and production flexibility.

High-Speed and High-Capacity Output

With a maximum extrusion speed of 400 meters per minute and capacity up to 180 kg/h, the line delivers efficient production for medium to large-scale operations.

Durable and Optimized Screw Technology

Both screws are treated with nitriding and chrome plating for excellent wear resistance, corrosion protection, and thermal stability, ensuring long-lasting and consistent extrusion quality.

Robust Mechanical Construction with Advanced Materials

Made from iron and steel, with hardened cylinders and thickened tube walls, the machine guarantees structural integrity, temperature consistency, and superior product quality.

Customizable Color and Compact Footprint

Defaulted in sky blue but fully customizable, the 24-meter compact production line fits efficiently into various plant layouts without compromising on output or operational ease.

Product Specification

|

Specification |

Detail |

|

Applicable Cable Diameter |

φ1 mm – φ10 mm |

|

Extruders |

φ70 mm + φ35 mm |

|

Material |

PVC, PE, XLPE |

|

Max Extrusion Capacity (φ70) |

180 kg/h |

|

Extrusion Capacity (φ35) |

≥13 kg/h |

|

Linear Velocity |

Up to 400 m/min |

|

Length of Production Line |

24 meters |

|

Installed Power Capacity |

Approx. 150 kg/h |

|

Color |

Sky Blue (Customizable) |

|

Screw Material (φ70mm) |

Alloy steel, nitrogen-treated, chrome-plated |

|

Screw Material (φ35mm) |

38CrMoALA, nitrided, hard chrome plated |

|

Compression Ratio (φ70mm) |

1:2.8 |

|

L/D Ratio |

70mm: 1:25, 35mm: 1:17 |

|

Center Height |

1000 mm |

|

Screw Speed (φ70mm) |

0–90 RPM |

|

Screw Hardness (φ35mm) |

HRC60~63 |

Product Applications

Double-Color Electrical Wire Production

Ideal for producing two-color insulated building wires, which help with quick circuit identification and wiring organization.

Building Cable Sheathing

Designed for the insulation and sheathing of BV, BVR, and RV building cables, commonly used in residential and commercial projects.

PVC and XLPE Insulated Cable Manufacturing

Supports a wide variety of thermoplastic and thermoset materials for producing standard or flame-retardant electrical cables.

Customized OEM Cable Projects

Highly suitable for customized cable production lines that require flexible material and diameter handling, including multilayer jacketing.

Low to High Volume Cable Factories

Efficiently meets the needs of both medium-scale and large-scale cable manufacturing plants with its high-speed continuous extrusion capability.

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost